Bulletproof glass serves as a critical protective measure for modern military armored vehicles, particularly in the front windshields of wheeled armored vehicles. These high-grade bulletproof glass panels not only meet operational requirements for driving and observation but also provide essential safety protection for drivers. However, due to limitations in thickness, weight, and cost, mass-produced armored vehicle bulletproof glass typically offers limited protection—capable of withstanding 7.62mm rifle bullets but ineffective against larger-caliber machine gun rounds and anti-vehicle sniper rifle projectiles. In most cases, additional reinforced flip-up armor panels are required to enhance defensive capabilities.

The photo above shows seven types of bulletproof glass for armored vehicles with different protection levels, with thicknesses of 18.5mm, 29.5mm, 44mm, 48mm, 62mm, 68.5mm and 130mm, displayed during the Russian "Army-2019" International Military Technology Forum. Below it are the corresponding defensive ammunition calibers, from left to right: 7.62X25mm, 7.62X39mm 7.62X54mm, 7.62X54mm, 7.62X54mm, 7.62X54mm, 12.7X108mm.

The 7.62×25mm round is a pistol cartridge, while the 7.62×39mm is a rifle cartridge (the AK-47),7.62X54mm round specifically refers to sniper rifle ammunition, and the SVD), 12.7X108mm round denotes large-caliber machine gun or sniper rifle rounds). Due to differences in propellant charge and cartridge length, even cartridges of the same caliber exhibit varying ranges, accuracy, and destructive power. For example, 7.62mm cartridges differ in length between pistols and rifles. Moreover, within the rifle category, NATO-standard and Warsaw Pact-standard cartridges have distinct lengths, with NATO-standard variants being slightly longer.

Generally speaking, bullets with longer trajectories demonstrate better flight stability and consequently higher accuracy when fired at the same caliber. The varying lethality of different ammunition types requires corresponding bulletproof glass with varying thicknesses. For instance, among the seven bulletproof glass models mentioned, four are rated 44mm, 48mm, 62mm, 68.5mm to withstand 7.62X54mm bullets, with protective ratings progressively increasing. The selection of specific glass grades should be determined through comprehensive evaluation of application scenarios, operational environments, and overall vehicle cost control. Take high-mobility off-road vehicles as an example: 44mm glass would be impractical for 68.5mm-rated applications. This decision involves both manufacturing cost considerations and the weight implications of bulletproof materials. If such tactical vehicles were to use 12.7mm-rated bulletproof glass for their entire exterior, the sheer weight alone would exceed several tons – rendering the vehicle practically obsolete.

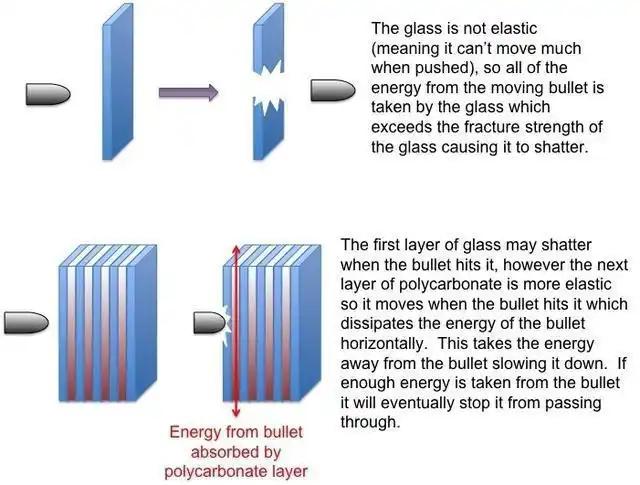

Current research indicates no inherent correlation between bulletproof glass thickness and light transmission/optical distortion. Ultra-thick multilayer bulletproof glass doesn't necessarily have inferior light transmission than thinner double-layer variants. This difference stems from variations in glass materials and interlayer compositions. Military armored vehicles typically use polycarbonate fiber interlayers, while bank counters and similar applications favor acrylic interlayers. These materials differ in cost and protective effectiveness, with each type offering distinct advantages.